Calculate manufacturing overhead costs by summing up your facility’s indirect expenses. View examples and formulas and learn how to calculate predetermined overhead rate. Indirect manufacturing costs are the labor and material needed for production, but that don’t add value to or end up in the products directly. Indirect material includes consumables as well as maintenance and service items.

How do you calculate total fixed manufacturing cost?

The costs from the overhead budget are also used for calculating the cost of finished goods inventory, which goes into the budgeted balance sheet. Additionally, this Oil And Gas Accounting budget will allow you to calculate a predetermined manufacturing overhead rate, which you can then use to measure your production costs. Understanding the total manufacturing cost is important for establishing competitive and profitable product pricing strategies. By knowing the exact cost to produce each unit, businesses can set prices that cover expenses and generate a desired profit margin. This knowledge prevents underpricing, which could lead to financial losses, and helps avoid overpricing, which might deter potential customers. Indirect labor refers to the wages of employees who support the manufacturing process but do not directly work on the product.

Step-by-Step Guide to Calculate Total Manufacturing Cost

Direct costs change based on the production period and how much product you manufacture. This generally includes materials and labor, which vary based on many factors, such as demand planning and staffing.Wondering how to calculate direct materials cost? Direct materials are calculated by subtracting the direct materials left at the end of the production period from the total amount of materials you started with and purchased in the period.

- It can be seen in the above graph, the TVC curve starts from the origin, which means that at zero level of output, the variable cost is also zero.

- Most, such as inventory values and purchases, will be in the ERP system while others will require accessing payroll, finance and the Computerized Maintenance Management System (CMMS).

- Calculate direct materials costs when doing a physical inventory and adding up all the opening and closing direct materials for some time.

- With all this valuable information under your belt, you can better track manufacturing costs as they pertain to your workforce.

- It’s useful to note that the same raw material might also be used as both direct and indirect material pools.

Formulas for calculating Total Manufacturing Costs

We’ve ignored these indirect costs for the sake of simplicity, but you really shouldn’t. Indirect costs refer to any necessary spending not directly connected to the manufacturing process. This includes (but is not limited to) the cost of electricity, rent, and so on. Today, we’ll be delving into the total manufacturing cost formula and how to use it. Many of our custom engineer and make-to-order customers often buy inventory directly to the job/project.

- This includes all materials that can be traced directly to the finished product.

- If it takes 3 direct labor hours to produce one unit, you would assign $12 in overhead to that unit.

- You want accurate and real-time data to increase your level of competitiveness in the market.

- Total manufacturing cost is important for accurate financial reporting and inventory valuation.

- To calculate your total direct material costs, you need to figure out your direct materials and calculate how much you spent on them.

- When figuring out direct material costs, it’s important to distinguish between direct and indirect.

The relationship between total manufacturing cost and productivity

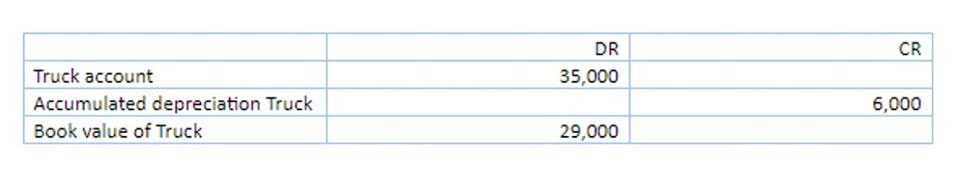

For example, salary of staff, rent on office premises, interest on loans, etc. Other names of fixed costs are Supplementary Cost, Overhead Cost, Unavoidable Cost, Indirect Cost, or General Cost. Fixed cost is the cost spent on fixed factors such as land, building, machinery, etc. Also, the payment made on these factors remains the same whether the output is small, large, or zero. Total manufacturing cost is the amount of money spent to manufacture a product, including overhead expenses, materials, and labor. There are also other (very important!) parts of these equations to account for.

Manufacturing Overhead Budget Example

Direct materials encompass the raw materials and components that directly contribute to the production of goods. These materials are transformed during the manufacturing process into the finished product. Examples include metals, plastics, electronic components, and any other materials that are integral to the final product’s how to calculate total manufacturing costs composition.

Identifying Manufacturing Cost Components

Direct material costs are the expenses on raw materials that are directly traceable to the finished product. For example, the wood, textile, and timber used to create chairs and tables would be considered direct material in a furniture manufacturing unit. Total manufacturing cost is an accounting metric that sums up all of the costs that go into https://diariocosta.com/accounting-software-for-sole-traders-freelancers-2/ manufacturing a company’s products. These include direct material and labor costs, as well as manufacturing overheads.

How to Calculate Total Manufacturing Cost Formula + Step-by-step Guide

Now you can determine the manufacturing overhead rate — this is the percentage of your monthly revenue that goes towards paying for overheads each month. To do this, divide the monthly manufacturing overhead by the value of your monthly sales, multiplying that by 100. However, there’s a lot more to properly calculating total manufacturing costs than just knowing the formula. The ultimate figure for total manufacturing cost, as it relates to a business’s income statement and overall profitability, is typically represented by the Cost of Goods Sold (COGS). COGS matches the expense of producing goods with the revenue generated from their sale within a specific period.

With features for task and resource management, workload and timesheets, our flexible software can meet the needs of myriad industries. Join the teams at Seimens, Nestle and and NASA that have already succeeded with our tool. There are other notifications you can receive by email or in the tool to alert you about activity and task reminders. Our collaborative platform lets you share files and comments with everyone no matter where or when.

Among these costs, you’ll find things such as property taxes that the government might be charging on your manufacturing facility. But they can also include audit and legal fees as well as any insurance policies you have. These financial costs are mostly constant and don’t change so they’re allocated across the entire product inventory. Direct materials are the raw goods that become an integral part of the final product and are directly traceable to its creation. These are the primary substances transformed during the manufacturing process.

Leave a Reply