TOKYO — A long robot entered a damaged reactor at Japan’s Fukushima nuclear power plant on Tuesday, beginning a two-week, high-stakes mission to retrieve for the first time a tiny amount of melted fuel debris from the bottom.

The robot’s trip into the Unit 2 reactor is a crucial initial step for what comes next — a daunting, decades-long process to decommission the plant and deal with large amounts of highly radioactive melted fuel inside three reactors that were damaged by a massive earthquake and tsunami in 2011. Specialists hope the robot will help them learn more about the status of the cores and the fuel debris.

Here is an explanation of how the robot works, its mission, significance and what lies ahead as the most challenging phase of the reactor cleanup begins.

Nuclear fuel in the reactor cores melted after the magnitude 9.0 earthquake and tsunami in March 2011 caused the Fukushima Daiichi nuclear plant’s cooling systems to fail. The melted fuel dripped down from the cores and mixed with internal reactor materials such as zirconium, stainless steel, electrical cables, broken grates and concrete around the supporting structure and at the bottom of the primary containment vessels.

The reactor meltdowns caused the highly radioactive, lava-like material to spatter in all directions, greatly complicating the cleanup. The condition of the debris also differs in each reactor.

Tokyo Electric Power Company Holdings, or TEPCO, which manages the plant, says an estimated 880 tons of molten fuel debris remains in the three reactors, but some experts say the amount could be larger.

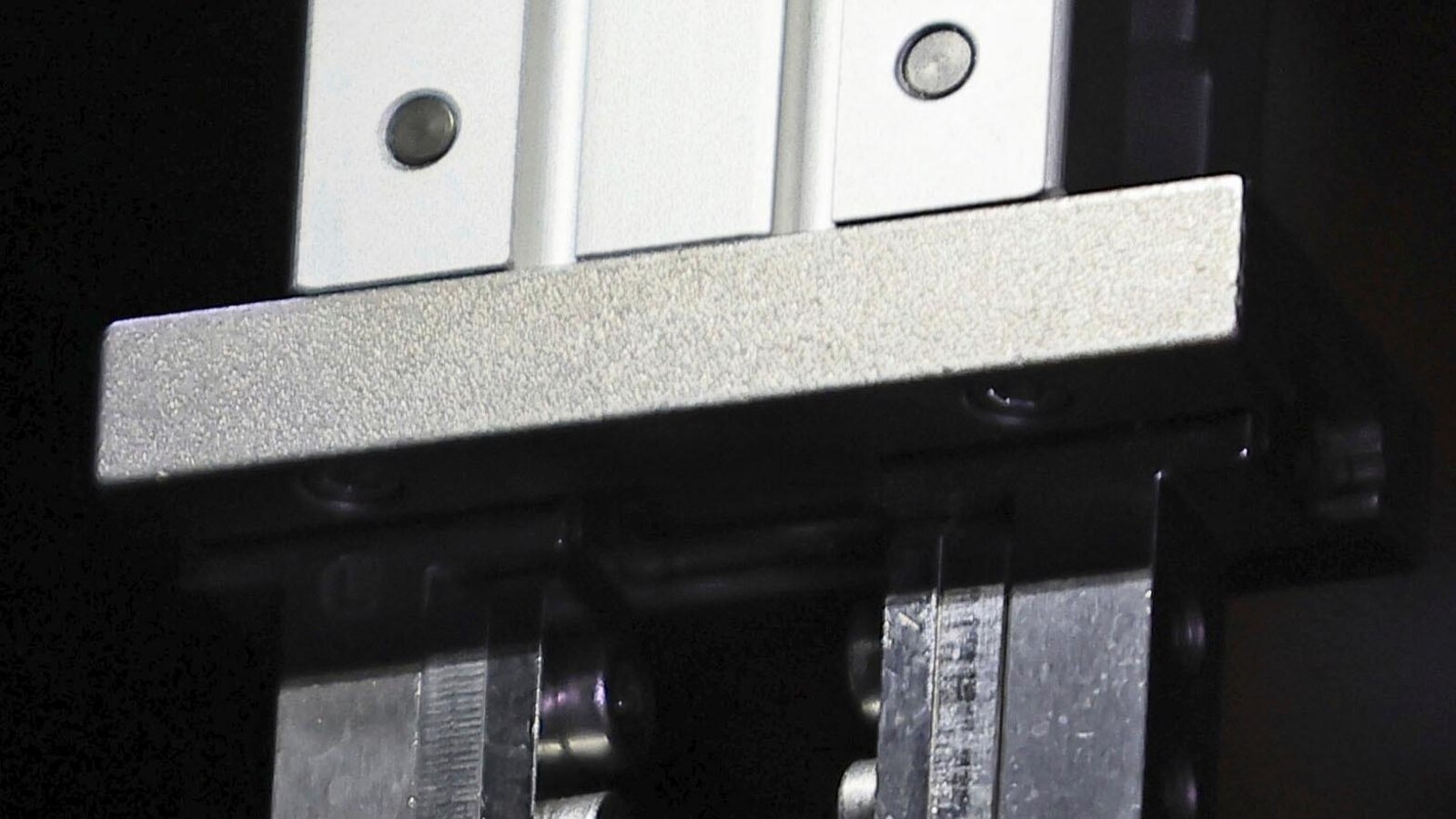

Workers will use five 1.5-meter-long (5-foot-long) pipes connected in sequence to maneuver the robot through an entry point in the Unit 2 reactor’s primary containment vessel. The robot itself can extend about 6 meters (20 feet) inside the vessel. Once inside, it will be maneuvered remotely by operators at another building at the plant because of the fatally high radiation emitted by the melted debris.

The front of the robot, equipped with tongs, a light and a camera, will be lowered by a cable to a mound of melted fuel debris. It will then snip off and collect a bit of the debris — less than 3 grams (0.1 ounce). The small amount is meant to minimize radiation dangers.

The robot will then back out to the place it entered the reactor, a roundtrip journey that will take about two weeks.

The mission takes that long because the robot must make extremely precise maneuvers to avoid hitting obstacles or getting stuck in passageways. That has happened to earlier robots.

TEPCO is also limiting daily operations to two hours to minimize the radiation risk for workers in the reactor building. Eight six-member teams will take turns, with each group allowed to stay maximum of about 15 minutes.

Sampling the melted fuel debris is “an important first step,” said Lake Barrett, who led the cleanup after the 1979 disaster at the U.S. Three Mile Island nuclear plant for the Nuclear Regulatory Commission and is now a paid adviser for TEPCO’s Fukushima decommissioning.

While the melted fuel debris has been kept cool and has stabilized, the aging of the reactors poses potential safety risks, and the melted fuel needs to be removed and relocated to a safer place for long-term storage as soon as possible, experts say.

An understanding of the melted fuel debris is essential to determine how best to remove it, store it and dispose of it, according to the Japan Atomic Energy Agency.

Experts expect the sample will also provide more clues about how exactly the meltdown 13 years ago played out, some of which is still a mystery.

The melted fuel sample will be kept in secure canisters and sent to multiple laboratories for more detailed analysis. If the radiation level exceeds a set limit, the robot will take the sample back into the reactor.

“It’s the start of a process. It’s a long, long road ahead,” Barrett said in an online interview. “The goal is to remove the highly radioactive material, put it into engineered canisters … and put those in storage.”

For this mission, the robot’s small tong can only reach the upper surface of the debris. The pace of the work is expected to pick up in the future as more experience is gained and robots with additional capabilities are developed.

TEPCO will have to “probe down into the debris pile, which is over a meter (3.3 feet) thick, so you have to go down and see what’s inside,” Barrett said, noting that at Three Mile Island, the debris on the surface was very different from the material deeper inside. He said multiple samples from different locations must be collected and analyzed to better understand the melted debris and develop necessary equipment, such as stronger robots for future larger-scale removal.

Compared to collecting a tiny sample for analysis, it will be a more difficult challenge to develop and operate robots that can cut larger chunks of melted debris into pieces and put that material into canisters for safe storage.

There are also two other damaged reactors, Unit 1 and Unit 3, which are in worse condition and will take even longer to deal with. TEPCO plans to deploy a set of small drones in Unit 1 for a probe later this year and is developing even smaller “micro” drones for Unit 3, which is filled with a larger amount of water.

Separately, hundreds of spent fuel rods remain in unenclosed cooling pools on the top floor of both Unit 1 and 2. This is a potential safety risk if there’s another major quake. Removal of spent fuel rods has been completed at Unit 3.

Removal of the melted fuel was initially planned to start in late 2021 but has been delayed by technical issues, underscoring the difficulty of the process. The government says decommissioning is expected to take 30-40 years, while some experts say it could take as long as 100 years.

Others are pushing for an entombment of the plant, as at Chernobyl after its 1986 explosion, to reduce radiation levels and risks for plant workers.

That won’t work at the seaside Fukushima plant, Barrett says.

“You’re in a high seismic area, you’re in a high-water area, and there are a lot of unknowns in those (reactor) buildings,” he said. “I don’t think you can just entomb it and wait.”